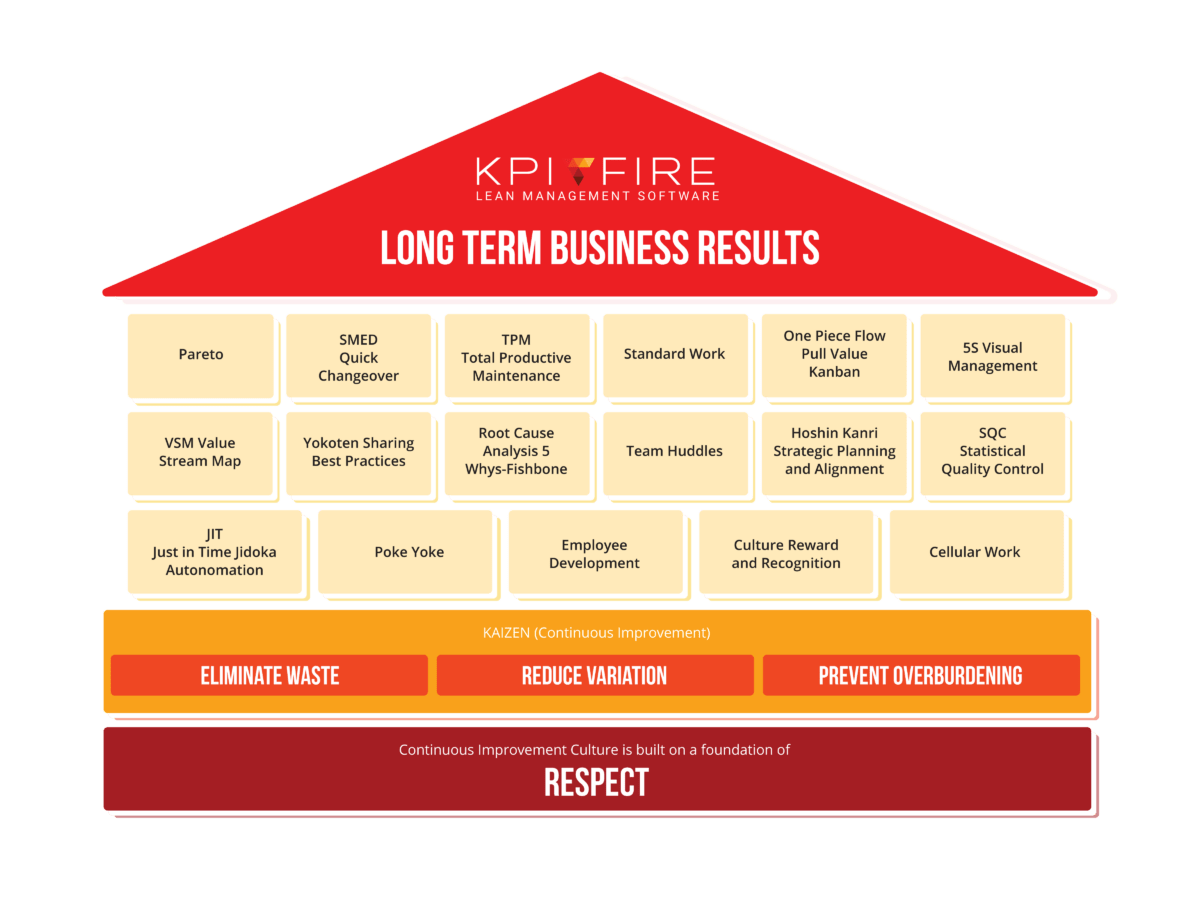

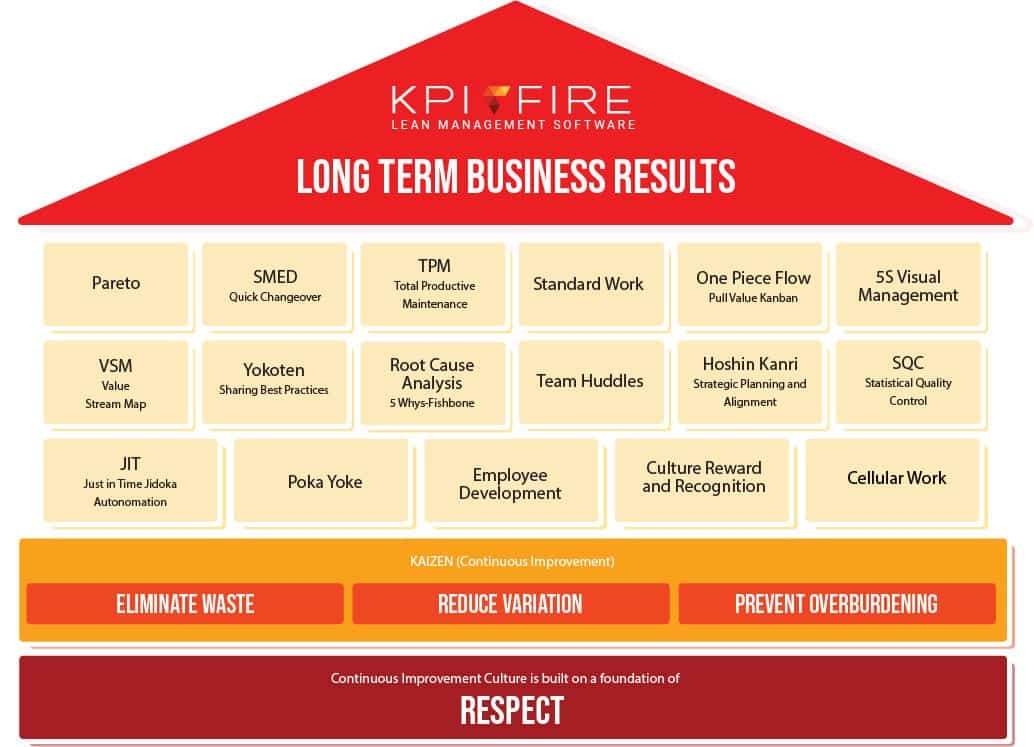

Continuous Improvement IS the Strategy.

The framework represented in this house of lean are some of the best building blocks that can lead your organization to greater long term business results and greater success. Become the master of these building blocks when building your own lean program.

The Foundation: Respect

Respect is important because it is a fundamental building block for healthy relationships and interactions with others. It allows individuals to feel valued and appreciated, and it creates a sense of trust and understanding. When people feel respected, they are more likely to be open and honest with others, which in turn leads to better communication and cooperation.

Respect also helps to foster a sense of community and belonging. When individuals respect each other and the group as a whole, it promotes unity and a shared sense of purpose.

Respect for the customer means not asking the customer to pay for things that do not add value for them. Eliminating wastes that increase price unnecessarily is a form of respect.

Respect for the employees means not overburdening them with unfair or unnecessary work or processes.

Respect for the company & shareholders means making sure that the work that is done by the company is done in a profitable way.

Respect for the work environment means making sure we are working in a sustainable way when it comes to resources and energy.

The 3 Primary Objectives of Lean:

Eliminate Waste

Eliminating waste tends to be the most common thought of as the primary objective of a Lean program. See this blog for “The 8 Wastes of Lean” to learn more about specific types of waste to target.

Reduce Variation

Lean and Six Sigma are often referred to in similar circles, the principles of Six Sigma are most well known for eliminating variations.

Prevent Overburdening

Overburdening employees is not a sustainable way to operate a business. Sure, you can survive with periods of intense work or overtime, but it will result in burnout, high turnover rates and increased costs in the long run.

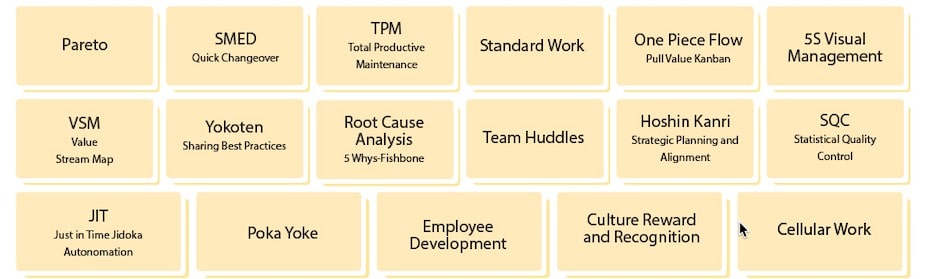

Pareto

The pareto principle is known as the 80/20 rule. That 80% of the effects come from 20% of the causes. A pareto chart is a very useful tool in Continuous Improvement as it can help you identify the few causes that can have the highest impact on your results. (learn more about Pareto Charts & the Pareto Principle here).

SMED

Single-minute exchange of dies (SMED) is a process used to reduce the time it takes to complete equipment changeovers. The term “single-minute” is a bit misleading—it doesn’t mean every changeover should only take one minute, but that every changeover should take less than 10 minutes, or a single-digit minute.

Continuously Improve With Our Latest News & Updates

Related Blog: Learning more about SMED

TPM: Total Productive Maintenance

Total Productive Maintenance (TPM) is a maintenance strategy that involves all employees in the organization, from operators to management, in the maintenance and improvement of equipment and facilities. The goal of TPM is to increase overall equipment effectiveness (OEE) by reducing downtime, increasing productivity, and improving product quality. TPM focuses on proactive maintenance, which is carried out regularly to prevent equipment failure and breakdowns. This includes regular inspections, cleaning, and lubrication, as well as minor repairs and adjustments. TPM also includes autonomous maintenance, where operators are trained to carry out basic maintenance tasks on their equipment, and planned maintenance, which is scheduled in advance to minimize downtime. By involving all employees in the maintenance process, TPM aims to increase their engagement and ownership of the equipment, and ultimately, improve overall organizational performance.

Standard Work

Standard work refers to the most efficient and effective way of performing a task or a process, as determined through analysis and improvement. It is a set of instructions that outlines the steps, methods, and sequences required to complete a task, as well as the necessary tools, equipment, and materials. Standard work also includes the time required to complete the task and the quality standards that must be met. The goal of standard work is to create a consistent, reliable, and efficient process that can be easily followed and improved upon.

One Piece Flow / Kanban

One Piece Flow (also known as single-piece flow or unit flow) is a production method that involves producing one item at a time, rather than producing items in batches. The goal of one piece flow is to reduce lead time and increase efficiency by eliminating the need to handle and store partially completed items.

Kanban is a visual system used to control the flow of work in a process, it is often used in conjunction with One Piece flow. Kanban cards or other visual signals are used to indicate when a new item is needed and when an item has been completed. This allows the production process to be pulled by the customer demand, rather than being pushed by a production schedule.

5S Visual Management

5S Visual Management is a workplace organization method that utilizes visual cues to improve efficiency, safety, and productivity. It is based on the 5S principles of Sort, Simplify, Sweep (or Shine), Standardize, and Sustain.

VSM Value Stream Map

A Value Stream Map (VSM) is a visual tool that helps to identify and analyze all the steps involved in a process or value stream, from the beginning of the process to the end product delivered to the customer. It is used to understand the flow of materials, information, and activities required to bring a product or service to the customer.

Yokoten

Yokoten is a Japanese term that refers to the process of taking a successful improvement method or practice that has been implemented in one area of an organization and spreading it to other areas.

Related Blogs: Yokoten, The Importance of Mistakes

Root Cause Analysis

Root Cause Analysis (RCA) is a method used to identify the underlying cause(s) of a problem or an incident. The goal of RCA is to understand the underlying causes of a problem, rather than just addressing its symptoms, in order to prevent recurrence and improve the overall system. Some common tools of RCA are the 5 Whys, and a fishbone diagram.

Related Blog: Finding Root Cause with The 5 Whys

Team Huddles

Team huddles are short, informal meetings that are held on a regular basis to keep team members informed and aligned. They are typically held daily or weekly, and are designed to be quick and efficient, taking only a few minutes to complete.

Related Blogs: Win the game of work, one Huddle at a time, Daily Huddle: the one meeting you should never go without, How to use a Huddleboard, How to create a Huddleboard in KPI Fire, Huddleboard Examples

Hoshin Kanri

Hoshin Kanri (also known as “Policy Deployment”) is a strategy management method that is used to align an organization’s objectives and goals with the actions and activities of its employees. It is a comprehensive approach to planning, execution, and review that helps organizations to achieve their long-term objectives and to continuously improve their performance.

Related Blogs: What is Hoshin Kanri?, How Hoshin Kanri works in KPI Fire

SQC: Statistical Quality Control

Statistical Quality Control (SQC) is a method of monitoring and controlling the quality of a product or process by using statistical methods. This can include techniques such as statistical process control (SPC), which uses statistical tools to monitor and control processes, and acceptance sampling, which uses statistical sampling to determine whether a batch of products meets the required quality standards. SQC also includes the use of control charts, which are graphical tools that can be used to monitor and control process performance. The goal of SQC is to identify and correct quality problems as early as possible in the production process in order to minimize the number of defective products and improve overall process efficiency.

Related Blog: How to use Control Charts

JIT Just in Time Jidoka Autonomation

Just-in-time (JIT) is a manufacturing philosophy that aims to improve efficiency and reduce waste by producing goods only as they are needed in the production process. Jidoka, also known as “autonomation,” is a key component of JIT production. Jidoka refers to the practice of using machines that can detect and correct problems on their own, without human intervention. This allows for the early detection of errors and quick correction, which helps to minimize waste and improve overall efficiency in the production process.

Related Blog: How start using Jikoka nd Andon

Poka Yoke

Poke yoke is a Japanese term that refers to a method of mistake-proofing a process in order to prevent errors from occurring. The goal of poke yoke is to make it impossible or highly unlikely for an operator to make a mistake, and to detect any errors that do occur as quickly as possible. This is done by designing the process and equipment in such a way that the operator is guided towards the correct actions, and any deviations from the standard are immediately flagged.

Related Blog: Poke Yoke: the power to improve quality

Employee Development

Employee development can take the form of specific training that employees go through during onboarding, or the development of career tracks that involve management and leadership training. “Belt” Programs such as white belt, yellow belt, green belt, black belt programs are popular. However none of them replaces a growth mindset. Change is the one thing that will never change. It is important that your employee development programs are training how to think and how to solve problems rather than simply training how to do a single job.

Culture/ Rewards & Recognition

Rewards and recognition can help create a good culture by encouraging positive behavior and performance. When employees are recognized for their hard work and achievements, they feel valued and appreciated, which can lead to increased motivation, job satisfaction, and commitment to the organization. Additionally, rewards and recognition can foster a sense of competition and camaraderie among employees, which can lead to improved teamwork and collaboration. Overall, rewards and recognition can help create a positive and productive work environment.

Related blogs: 5 Rituals for an Execution Culture, 7 Habits of Continuous Improvement , The common language of Continuous Improvement

Cellular Work

Cellular work refers to a manufacturing system in which small groups of workers are responsible for all aspects of the production process for a specific product or product family. The goal of cellular work is to create a flexible, efficient, and low-waste manufacturing process by reducing or eliminating the need for large assembly lines and dedicated machinery. Instead, small teams of workers use a variety of tools and machines to perform all of the necessary operations for a product, allowing them to quickly adapt to changes in demand or product design. This approach is known to improve responsiveness, quality, and overall efficiency.