Imagine doing the Gemba Walk and hearing machines hum in perfect harmony, seeing workers move with practiced grace, and waste is as rare as a unicorn. This isn’t a utopian dream; it’s the reality forged by the Toyota Production System (TPS), a revolutionary approach to manufacturing that has transformed Toyota into a global powerhouse. What is the significance of the TPS in the world of Lean today – and how can you leverage its core principles? Read on to find out.

What is the TPS?

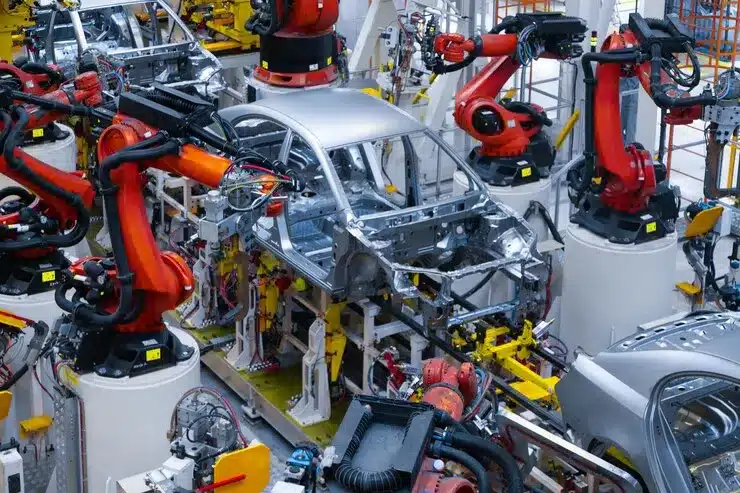

The Toyota Production System (TPS) is a comprehensive and integrated management philosophy and set of practices developed by Toyota Motor Corporation. It aims to achieve the optimal production of goods by eliminating waste and continuously improving processes.

What are the core principlesof the TPS?

- Jidoka (automation with a human touch): Machines stop automatically when a problem arises, preventing defects and ensuring quality.

- Just-in-Time (JIT): Producing only what is needed, when it is needed, minimizing inventory and waste.

- Kaizen (continuous improvement): Every step of the process is constantly evaluated and improved, no matter how small.

- Respect for People: Workers are empowered and engaged, fostering ownership and creativity.

What are the Benefits of using the TPS?

- Reduced waste and cost: TPS eliminates inefficiencies and non-value-added activities, leading to cost savings.

- Increased quality: Jidoka and other practices ensure consistent high-quality products.

- Improved efficiency: Just-in-Time production minimizes lead times and inventory, making operations more agile.

- Boosted employee engagement: Respect for people fosters a more engaged and motivated workforce.

- Shorter lead times: Cars that once took weeks to build now roll off the assembly line in mere hours.

TPS Applications

The impact of TPS extends far beyond the factory floor. It has been adopted by companies across industries, proving its universal applicability.

TPS is primarily used in manufacturing, but its principles can be applied to any industry, including healthcare, (Lean) software development, and even personal life.

TPS has revolutionized manufacturing and inspired other lean production methodologies. It has helped Toyota become a global leader in quality and efficiency.

Its principles are widely adopted while promoting continuous improvement and waste reduction.

Continuously Improve With Our Latest News & Updates

TPS in the Digital Age: Embracing New Technologies for Continuous Improvement

The Toyota Production System (TPS), renowned for its relentless pursuit of waste elimination and continuous improvement, is no relic of the past. In the age of digital transformation, TPS is not only thriving, but evolving, embracing new technologies to further refine its legendary efficiency and effectiveness.

From paper Kanban boards to real-time data dashboards, TPS is undergoing a digital metamorphosis. Let’s delve into how these advancements are propelling TPS into the future.

Big Data and Analytics: Fueling Smarter Decisions

TPS thrives on data. Today, vast amounts of real-time data on production processes are collected, and advanced analytics tools sift through this data, uncovering hidden patterns and insights. This empowers managers to:

- Predict and prevent equipment failures before they disrupt production.

- Optimize production schedules for maximum efficiency and minimal waste.

- Identify areas for improvement with pinpoint accuracy, driving continuous Kaizen.

Inspired by the principles and techniques of the TPS, KPI Fire is KPI Software for the 21st century that enables and empowers teams with the tools they need to continuously improve and achieve a certain level of business excellence. Be sure to request your demo version to on-board your team and identify a particular area of improvement with our VP of Sales, Randy Clark.

Relevant External Sources

-

The Toyota Production System & Lean Manufacturing: A Practical Guide for Improving Any Business (MIT Sloan Management Review): This article offers a concise overview of the Toyota Production System (TPS) principles, explaining its foundations like Jidoka (automation with a human touch), Kanban (pull production), and continuous improvement.

-

Toyota Production System: The Management Philosophy That Changed the World (Lean Enterprise Institute): This website from the leading TPS authority provides in-depth information on the system’s history, core principles, tools, and case studies of successful implementation outside the automotive industry.

-

The Toyota Production System: A Case Study of Continuous Improvement (Harvard Business Review): This classic article dives into the cultural aspects of TPS, highlighting the company’s focus on employee engagement, problem-solving, and respect for human dignity.