This article delves into the essence of Jidoka, exploring its meaning, fundamental principles, and the significant benefits it brings to manufacturing operations. Whether you are a seasoned manufacturing professional seeking to optimize your processes, a business leader aiming for enhanced quality and reduced waste, or simply curious about the power of Six Sigma and Lean methodologies, this exploration will provide valuable insights into how Jidoka can revolutionize your approach to production. Let’s move beyond simple automation and discover how Jidoka empowers both machines and people to build quality into every step of the manufacturing journey.

Main Takeaways From This Article:

- Jidoka is “automation with a human touch” or “autonomation” that empowers machines to detect abnormalities and automatically stop production to prevent the creation of defective products and minimize waste.

- The integration of Jidoka with the Andon system provides immediate visual and sometimes auditory alerts when a problem occurs, facilitating rapid communication and response.

- Jidoka follows a structured four-step process: Detect an Abnormality, Stop Production Automatically, Fix the Immediate Problem, and Prevent Future Defects.

- Implementing Jidoka offers significant benefits, including improved visibility and transparency of production issues, boosted productivity and efficiency through reduced rework, minimized waste of resources, lower operational costs and downtime, enhanced product quality, empowered operators, and improved overall production processes.

- Sustaining Jidoka for continuous improvement requires ongoing commitment, adherence to standardized workflows, and the use of data-driven tools like KPI Fire to monitor performance, analyze defect patterns, and track the effectiveness of corrective actions.

What is Jidoka?

Jidoka, often described as “automation with a human touch” or “autonomation,” is a powerful principle in the house of Lean, and also in the realm o Automobile Manufacturing where machines are equipped with the intelligence to detect abnormalities or defects in the production process. When an issue is identified, the machine automatically stops, preventing the continuation of faulty production and minimizing waste.

Within the history of business improvement methodologies, this concept is one of the two core pillars of the Toyota Production System (TPS), alongside Just-in-Time (JIT) manufacturing, forming the foundation of efficient and high-quality production. A key tool used to implement Jidoka is the andon, a visual signaling system that alerts personnel to a problem, allowing for immediate investigation and resolution.

The History of Jidoka and the Toyota Production System

Sakichi Toyoda revolutionized automobile manufacturing in the early 20th century by pioneering Jidoka in the textile industry. Frustrated by the continuous production of flawed fabric due to broken threads, he invented a self-stopping loom that automatically halted operation upon detecting an issue. This ingenious concept of autonomous defect detection was later adapted and rigorously applied by Toyota as they entered the automotive sector.

By integrating Jidoka into their production lines, Toyota ensured that defective parts were immediately identified and prevented from moving further down the assembly process. This focus on in-process quality control became a defining characteristic of the Toyota Production System (TPS). Over time, Jidoka’s effectiveness in minimizing waste and maximizing quality cemented its place as a core principle of Lean manufacturing, profoundly impacting global production methodologies.

Jidoka and Andon

Andon is a crucial visual signaling system within a Jidoka-enabled environment, designed to immediately alert workers and supervisors to any production issues that arise. These signals, often in the form of lights, audible alarms, or digital displays, can be activated in two ways: manually by an operator who identifies a problem, typically by pulling a cord or pressing a button, or automatically by the machine itself when it detects an abnormality as part of its Jidoka capability.

Jidoka and Andon are intrinsically linked, working in tandem to prevent the proliferation of defects. While Jidoka is the principle that empowers the system to automatically or manually halt production upon detecting an issue, the Andon system provides the immediate visual and sometimes auditory cue that a problem has occurred and requires attention from the relevant team to investigate and resolve. This rapid communication facilitated by Andon is essential for the effective implementation of Jidoka.

The Four Steps of Jidoka in Lean Manufacturing

Jidoka in Lean Manufacturing follows a structured four-step process that ensures efficient detection and resolution of production issues, ultimately leading to enhanced quality.

1. Detect an Abnormality

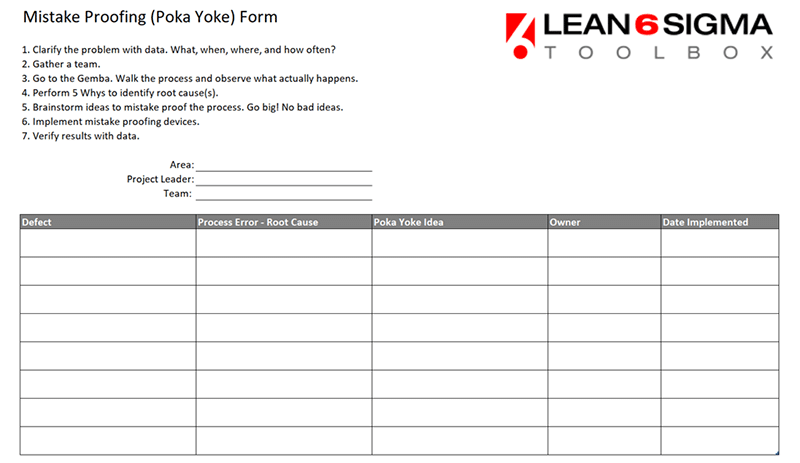

Jidoka empowers machines with the ability to detect deviations from standard conditions or the presence of defects in real time. This is often achieved through the integration of various sensors, error-proofing mechanisms (poka-yoke), and sophisticated monitoring systems within the equipment. When an abnormality is sensed, the Andon system may be triggered, providing immediate visual or auditory alerts to operators and supervisors. This early detection is paramount as it acts as the first line of defense against quality issues, preventing further processing of defective items and minimizing potential waste and rework.

Poka Yokes ensure that the right conditions exist before a process step is executed, and thus preventing defects from occurring in the first place. Where this is not possible, Poka Yokes perform a detective function, eliminating defects in the process as early as possible.

Once the problem is resolved and work continues, the occurrence is logged as part of a continuous improvement system.

2. Stop Production Automatically

Machines designed with Jidoka capabilities are equipped to autonomously halt production the moment a defect or irregularity is sensed. This automatic stoppage is a fundamental aspect of the principle, preventing defective items from progressing further along the production line. The significance of this immediate action lies in its ability to contain quality issues early, before more value is added to a faulty product or it contaminates subsequent processes. By stopping the line promptly, Jidoka facilitates a focused response to the problem, enabling quicker diagnosis and resolution, ultimately reducing waste, minimizing rework, and safeguarding product quality.

3. Fix the Immediate Problem

When a machine implementing Jidoka automatically stops due to a detected abnormality, trained operators promptly intervene to diagnose the immediate cause of the stoppage. Their role is to quickly identify the specific issue, such as a misaligned part, a broken tool, or a material jam, and take the necessary corrective actions to restore the machine to normal operation. This swift intervention is critical in preventing the further production of defective items. By addressing the problem at its source and ensuring the machine is functioning correctly before restarting, operators effectively prevent flawed products from being passed along to subsequent stages of the manufacturing process, thus maintaining quality and minimizing downstream complications.

4. Prevent Future Defects

Jidoka goes beyond simply stopping and fixing immediate problems; it actively fosters a culture of continuous improvement by emphasizing the prevention of future defects. When an abnormality occurs and the immediate issue is resolved, Jidoka mandates a thorough investigation to identify the underlying root cause of the problem. This in-depth analysis delves into the “why” behind the defect, examining factors such as equipment design, process parameters, material quality, operator training, and work instructions.

By pinpointing the fundamental source of the issue, teams can implement permanent corrective actions that eliminate the conditions allowing the defect to occur in the first place. This proactive approach not only reduces the likelihood of recurring defects, leading to more consistent product quality, but also contributes to the optimization of the entire production process by enhancing efficiency and reducing waste over the long term.

Benefits of Jidoka in Lean Manufacturing

Jidoka in Lean Manufacturing delivers substantial advantages by proactively embedding quality into the production process, driving efficiency through reduced waste and downtime, and enabling greater operational flexibility to adapt to unforeseen issues.

Improves Visibility and Transparency

Jidoka makes production issues immediately apparent through the activation of Andon systems and the halting of machinery. This real-time visibility allows teams to quickly understand where problems are occurring and the severity of the disruption. For example, a red light flashing above a specific workstation instantly signals a problem, enabling supervisors and support staff to converge on the issue without delay, fostering a transparent and responsive production environment.

Boosts Productivity and Efficiency

By addressing problems as soon as they arise and preventing the creation of further defects, Jidoka significantly reduces the time and resources spent on rework, troubleshooting, and correcting defective products later in the process. Imagine an automotive assembly line where a faulty weld is immediately detected and the line stops; this prevents hours of downstream work on a defective chassis, dramatically improving overall throughput and efficiency compared to discovering the flaw only at final inspection.

Reduces Waste

The principle of stopping production when a defect is detected inherently minimizes various forms of waste. By preventing the continued processing of faulty materials, Jidoka avoids the waste of raw materials, energy, and labor that would otherwise be invested in creating unusable products. For instance, in a textile mill using Jidoka looms, the automatic stop upon thread breakage prevents the production of yards of flawed fabric, directly reducing material waste and the associated costs.

Lowers Costs and Downtime

Early detection and resolution of defects through Jidoka translate directly into lower operational costs and reduced downtime. By preventing the accumulation of defects, organizations avoid expensive product recalls, extensive rework efforts, and significant production delays that can result from dealing with widespread quality issues discovered late in the process. A food processing plant with Jidoka systems that halt production upon detecting contamination can avoid costly recalls and reputational damage, ultimately saving significant amounts in the long run.

Enhances Product Quality

Jidoka’s core focus on building quality into the process, rather than relying solely on end-of-line inspections, ensures that only defect-free products proceed through the manufacturing stages. This commitment to in-process quality control strengthens customer trust and significantly reduces the incidence of warranty claims, returns, and negative feedback. A company manufacturing electronics with Jidoka-enabled testing stations at each stage can guarantee a higher quality final product, leading to greater customer satisfaction and loyalty.

Empowers Operators

Jidoka shifts a degree of responsibility for quality directly to the frontline workers, empowering them to take ownership of their processes and halt production if they identify an issue. This fosters a proactive problem-solving culture where teams are actively engaged in continuous improvement initiatives, contributing their valuable insights and experience. For example, an operator on a machining line who can stop the process upon noticing an unusual vibration is not just a button-pusher but an active participant in maintaining quality standards.

Improves Production Processes

The inherent requirement of Jidoka to investigate the root cause of every production stoppage leads to ongoing, long-term improvements in the underlying production processes. By systematically identifying and eliminating the sources of defects, organizations can increase the reliability and standardization of their operations, resulting in more stable and predictable outcomes. Over time, the cumulative effect of these continuous improvements, driven by the principles of Jidoka, leads to a significantly more robust and efficient manufacturing system.

Implementing Jidoka in Manufacturing

While Jidoka is a powerful principle within Lean Manufacturing, its successful integration into any manufacturing operation necessitates strong commitment from management and a well-defined, structured implementation approach.

1. Assess Current Production Processes

The initial step involves a thorough evaluation of existing manufacturing processes to pinpoint areas where defects frequently arise and to understand the current methods for identifying and managing these issues. This assessment is crucial for establishing a baseline and identifying opportunities where Jidoka principles and technologies can have the most significant impact. By understanding the current state, organizations can strategically target the implementation of automated detection and response mechanisms for maximum effectiveness.

2. Integrate Automated Detection Systems

This step focuses on the practical application of technology to enable machines to autonomously detect abnormalities. Installing sensors, implementing Andon visual signaling, and potentially integrating AI-powered machine learning tools allows for real-time monitoring and identification of defects. Establishing clear and accurate criteria for what triggers an alert or stoppage is vital to prevent nuisance alarms and ensure that the system effectively identifies genuine quality issues, leading to more reliable and efficient defect detection.

3. Train Operators on Jidoka Principles

Educating and empowering the workforce is fundamental to successful Jidoka implementation. Operators need comprehensive training on the principles of Jidoka, including their authority and responsibility to stop production when a defect is suspected or detected. Furthermore, they should be trained on basic problem-solving techniques to contribute to root cause analysis and the implementation of corrective actions, fostering a culture of ownership and continuous improvement at the operational level.

4. Establish Standardized Workflows for Response

Defining clear and standardized operating procedures (SOPs) for responding to a detected defect is essential for an efficient Jidoka system. This includes outlining the steps to be taken when production stops, clearly assigning roles and responsibilities for investigation, immediate fixes, and escalation if necessary. Well-defined workflows ensure a coordinated and timely response, minimizing downtime and maximizing the effectiveness of the Jidoka system in preventing the further propagation of defects.

5. Use Data for Continuous Improvement

To ensure Jidoka remains effective and evolves over time, it’s crucial to implement regular performance reviews and leverage data analytics. Utilizing tools like KPI Fire Continuous Improvement Software for tracking and reporting allows organizations to analyze the frequency and types of defects detected, the effectiveness of root cause analysis, and the efficiency of response workflows. This data-driven approach enables continuous improvement by identifying trends, highlighting areas for further optimization, and refining the Jidoka implementation for sustained quality and efficiency gains.

Sustaining Jidoka for Continuous Improvement with KPI Fire

Jidoka fundamentally transforms manufacturing by embedding quality directly into the production process. By empowering machines and operators to autonomously detect abnormalities and halt production, it prevents the proliferation of defects, leading to significantly enhanced product quality and reduced rework. This proactive approach minimizes the waste of materials, time, and effort associated with producing faulty goods, contributing to a more efficient and cost-effective operation.

Furthermore, Jidoka fosters a culture of ownership and continuous improvement by enabling operators to take immediate action and participate in problem-solving. The transparency provided by systems like Andon ensures that issues are quickly visible and addressed. The data generated from Jidoka-driven stoppages and resolutions, especially when tracked and analyzed with tools like KPI Fire, provides valuable insights for identifying trends, understanding root causes, and implementing long-term corrective actions. This iterative process of detection, response, analysis, and improvement ensures that the benefits of Jidoka are not static but rather contribute to an ever-evolving and increasingly reliable production system.

Sustaining the benefits of Jidoka and fostering continuous improvement demands ongoing vigilance, adherence to standardized workflows, and a commitment to iterative refinement. This crucial aspect can be significantly streamlined through the adoption of performance tracking and process automation tools. These technologies provide the necessary infrastructure to monitor the effectiveness of Jidoka principles, ensure consistent application of standardized responses, and drive data-informed decisions for continuous optimization.

KPI Fire plays a pivotal role in helping manufacturers sustain their Jidoka initiatives by offering real-time visibility into production performance and quality metrics. Its structured workflow capabilities ensure that the defined response protocols for detected abnormalities are consistently followed. Moreover, KPI Fire’s robust data analytics and reporting features provide invaluable insights into defect patterns, root cause analysis effectiveness, and the impact of implemented corrective actions. This data-driven approach empowers manufacturers to identify areas for further improvement, refine their Jidoka processes, and ultimately achieve enhanced production quality and efficiency.

Ready to take your Lean initiatives to the next level and experience the power of sustained Jidoka? Schedule a demo of KPI Fire today and discover how our platform can provide the real-time visibility, structured workflows, and data-driven insights you need to optimize your production processes and achieve lasting improvements.