Learn how to identify, measure, and communicate both types of savings to drive results and win executive support.

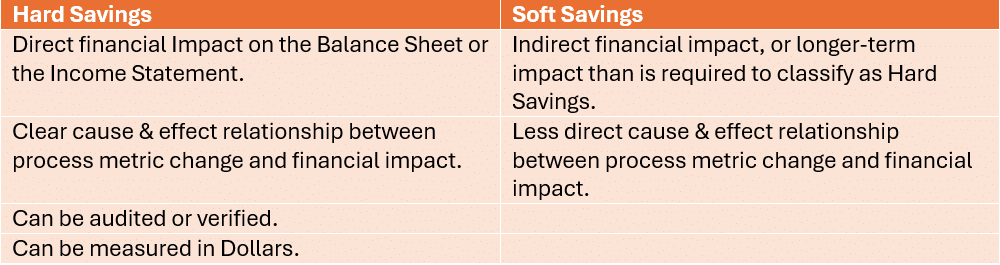

Traditionally, savings fall into two categories: hard savings and soft savings.

What are Hard Savings?

Hard savings are directly measurable and quantifiable financial benefits. They are typically easy to calculate and can be seen directly on a company’s profit and loss statement.

Hard savings reduce expenses and result in a financial improvement. They are directly attributed to an actual expense. There should be no confusion about how much was actually saved, as there is an invoice, payroll stub, bill, receipt, or the like associated with the expense.

Potential savings are a form of hard savings but require some type of action or decision before they occur. One example is a project that upgrades the design of an existing product. Until the redesign is implemented, the savings can’t be counted.

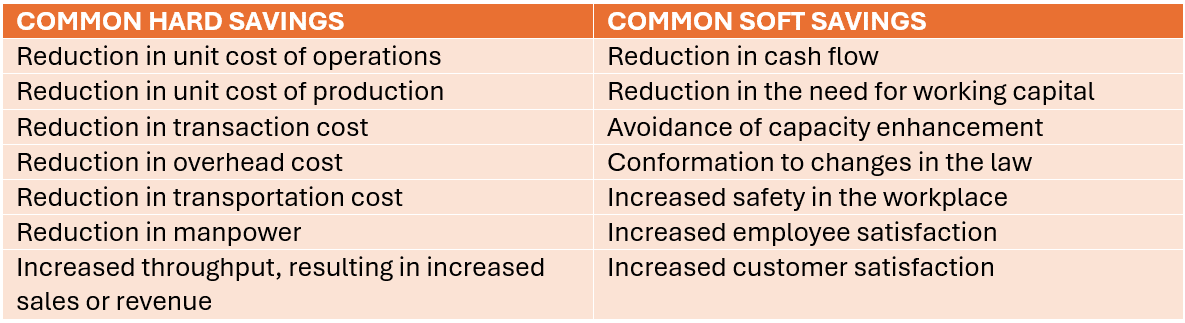

Examples of Hard Savings

- Reduced costs of goods sold (COGS)

- Reduced operating expenses

- Increased revenue

- Reduction in transaction cost

- Lower overhead costs

What are Soft Savings?

Soft savings are indirect financial benefits that are more difficult to measure and quantify. They can still be significant, but they often require estimation or modeling to calculate.

Soft savings tend to fall into two basic categories.

The first is the intangibles– lower frustration, improved job satisfaction, shorter lead times, greater trust, are all extremely difficult to directly apply dollar values to. All of them impact the bottom line. The problem is that it’s difficult to quantify how much the savings will impact the profit and loss statement.

The second category of soft savings are those that result in savings, but rely upon projections and estimates so a hard value can’t be assigned.

Consider the addition of a piece of safety equipment to machine. Intangible savings come from the increased job satisfaction that employees will experience from feeling that their employer cares about them. But there is also a potential hard savings in medical or legal costs if an employee was injured. The problem is that even though this would ultimately be a quantifiable expense, there is simply too much speculation to apply an actual dollar value to it.

Soft savings are, in fact, real savings. Companies save money when employees are more satisfied. For example, acquisition costs go down because satisfied employees are more likely to land new business than disgruntled ones. Consequently, they are also more likely to appease upset customers. Both of these impact the bottom line.

Examples of Soft Savings:

- Improved employee productivity

- Reduced customer churn

- Increased brand reputation

- Reduced risk

Lean is all about what can be quantified and measured. It’s not surprising that most organizations prefer to measure success in terms of hard savings—dollars to the bottom line now. And are less impressed with soft savings—the possibility of dollars to the bottom line in the future.

A good way to estimate the potential value of a project is to calculate savings if the problem was completely eliminated.

Join 50,000+ Leaders Improving Projects with KPI Fire

Get expert tips on Lean Six Sigma, strategy, and productivity — straight to your inbox every week.

Subscribe for Weekly Insights

100% Free · No Spam · Unsubscribe Anytime

Hard vs Soft Savings – Striking the Balance

The relationship between hard and soft savings in Lean projects is a complex one. While hard savings provide a clear and immediate return on investment, soft savings often lay the foundation for sustainable improvement. Here’s where the balance really comes into play.

Lean projects often start with a focus on hard savings. They aim to streamline processes, reduce waste, and cut costs—all measurable outcomes that can be easily quantified. However, a Lean initiative that exclusively prioritizes hard savings may risk overlooking the broader picture.

This is where soft savings come into play as essential complements to hard savings. Improved morale and increased customer satisfaction, for example, may not show up directly on the balance sheet, but they can have a cascading effect on productivity and profitability over time. By recognizing and nurturing these soft savings, organizations can ensure the longevity and resilience of their Lean transformations.

- Firstly, it’s crucial to set clear objectives and key performance indicators (KPIs) that encompass both hard and soft metrics. This ensures that the team’s efforts are aligned with the organization’s overall goals, including both immediate cost reductions and long-term value creation.

- Secondly, ongoing measurement and continuous improvement are essential. Lean projects are not one-time endeavors; they’re ongoing processes that demand regular evaluation. By tracking both hard and soft savings over time, organizations can adjust their strategies to maximize their impact.

- Lastly, fostering a culture of continuous improvement and employee engagement is key to reaping the benefits of soft savings. When employees feel valued and motivated, they are more likely to contribute to innovation and customer satisfaction, driving long-term, sustainable success.

Calculate Project Benefits – Free Calculatator

Instantly Calculate Project Savings & Benefits!

Quickly determine the exact hard and soft financial impact of your Lean or Six Sigma projects—in just minutes. Download our free, proven Excel template today.

- 100% Free

- No tools required

Hard vs Soft Savings: Examples of the Ideal Balance

We’ve compiled some examples of how hard and soft savings can mutually benefit one another for the greater good of an organization:

- A company invests in new software that reduces the time it takes to process orders. This results in hard savings in the form of reduced labor costs. It also results in soft savings in the form of improved customer satisfaction, as customers are now receiving their orders more quickly.

- A company implements a new employee training program that results in a decrease in accidents and injuries. This results in hard savings in the form of reduced insurance costs. It also results in soft savings in the form of increased employee morale and productivity.

- A company launches a new marketing campaign that increases brand awareness and leads to more sales. This results in hard savings in the form of increased revenue. It also results in soft savings in the form of increased customer loyalty and repeat business.

Key Take-away: Process Metrics vs. Financial Impact

In making the determination between Hard vs. Soft Savings, remember to think about the process metric which was changed and how directly that change will translate into direct business financial impact. If the impact is direct, it is more likely to be a Hard Savings Impact. If the impact is less direct, or depends on multiple other assumptions, or may take a longer time to translate into dollars, then the project may be generating Soft Savings.

Hard Savings vs Soft Savings Guidelines Summary

Creating a continuous improvement culture drives cost savings over time. Having a team of empowered employees that attacks problems can have a tremendous impact on profit.

– Don’t confuse hard and soft savings with cost avoidance. They’re two different categories. You can have an actual hard savings—as in when you save enough space that you can stop renting a production facility—or you can avoid the hard cost of having to rent a new facility to handle expansion. Both situations involve hard savings.

– Be accurate when tallying hard savings. There’s a tendency to inflate savings when reporting on a project. Resist the urge to be overly aggressive in assigning credit. This is particularly important with Hard Savings. Your creditability and the programs creditability will be negatively affected if you claim Hard Savings that can’t be audited or verified.

– Don’t double count the same savings. This is common when two continuous improvement teams both report that they saved the same money. This is very important for maintaining credibility of a Lean program. Reported savings must make it to the bottom line to keep naysayers from having ammunition in resisting change.

– Don’t neglect soft savings at the expense of hard savings. Some soft savings, especially those linked to job satisfaction, can pay off much more than a hard savings. Be careful, though. Soft savings are extremely difficult to calculate.

Watch the videos below to discover a third savings category and the 6 steps to calculating and communicating project value.

How to communicate the type of impact your improvement project generated

As the champion of Lean Six Sigma in your organization you’re excited to celebrate the successes of your improvement projects. Maybe you’ve already identified what needs to be improved and you know which processes are involved in creating your problem. Perhaps you’ve even determined the current level of performance. Now you are determining which type of savings the project will create.

As a general rule, you want all of your projects to produce a financial benefit—either directly or indirectly—through cost reductions, revenue growth, balance sheet improvements, or accomplishing strategic goals.

In addition, cost improvements come from reductions in labor, inventory, material, cost of money, scrap, excess equipment, space, and so on.

Prefer to Learn by Watching?

Check out these quick videos to see how KPI Fire helps teams capture and report both hard and soft savings across their improvement projects

Concluding the Interplay between Hard and Soft Savings

The interplay between hard savings and soft savings in Lean projects is a dynamic one. While hard savings provide immediate financial benefits, soft savings pave the way for enduring improvements and resilience in the face of change.

It is important to note that the distinction between hard and soft savings is not always clear-cut. Some savings may be considered both hard and soft, depending on how they are measured.

When evaluating the potential benefits of a project or initiative, businesses should consider both hard and soft savings. By doing so, they can make more informed decisions about how to allocate resources and improve their bottom line.

To achieve the full potential of Lean initiatives, organizations must recognize the value of both, measure what matters, and continuously adapt their strategies to strike the right balance between what can be counted and what truly counts.

Turn Ideas into Measurable Business Results – Book Your Free Demo Today!

Join world-class companies that have tracked and saved over $1.4 Billion with KPI Fire.

- Track Cost Savings & ROI in Real Time

- Align Strategy with KPI Metrics

- Drive Execution & Engage Teams

Schedule a 30-minute demo to discover how KPI Fire can boost your business.